Views: 16 Author: Site Editor Publish Time: 2018-05-17 Origin: Site

Every month Sieg-Huao has a regular out-put of investment casting auto parts made from stainless steel 316 and 316L which take a very high percentage of sales market. Today we will bring you to our production site to look through some process steps of one stainless steel auto part with the tooling number 9788 which means our 9788th investment castings in our foundry.

After getting many wax patterns from wax injection process, we will move to the wax tree assembling. The worker glues each pattern to a tree-like structure. Then the trees are dipped in a ceramic based slurry and showered in a very fine silica based mixture. The foundry uses a fully automated system molding that rotates the parts for an even coating. This process is repeated until the desired wall thickness is achieved.

Wax Tree Assembling |  Wax Tree |

dipping |  fully automated system |

After hardening, drying and de-waxing, the empty shells are formed. Then the shells are then fired in the kiln at a temperature of 900℃ to prepare for the investment casting.

drying |  baking |

The shells will then be reheated before the casting process begins. The stainless steel is then melted using an electromagnetic induction furnace which induces eddy currents within conductors by constantly changing the magnetic field. Eddy currents create heating effects to melt the metal internally. The stainless steel is heated to 1612℃ and the shells are preheated t0 1300℃, the casting process can begin. Individual casting molds are removed from the kiln and held below the furnace. The operator then pours the molted steel into the investment casting molds. The casting molds are then left to cool naturally on a conveyor belt. Once cooled, the steel can be removed from the mold. And finally we get the finished metal parts.

The parts are waiting for secondary machining in the CNC machining center.

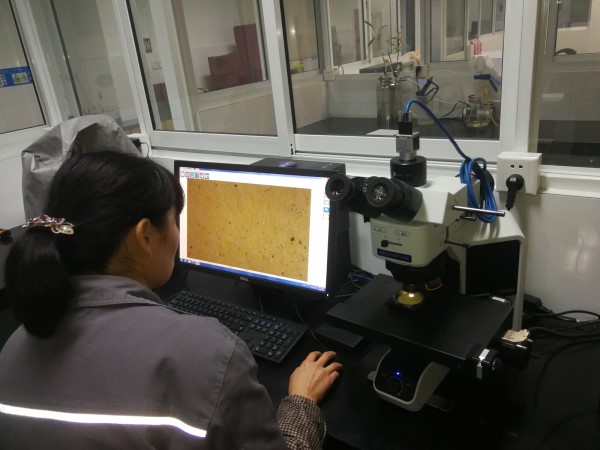

The parts are under inspection in the lab.

The investment casting parts are packaged in carton with suitable protective dividers. Each client may have different packing requirements. As usual we use carton plus outside wooden case which is strong enough for long distance sea shipping.

SIEG-HUAO is a professional steel investment casting supplier with advanced investment casting process. What we rely on are the excellent products, high quality and competitive prices. If you have any interests then come to us. Looking forward to your attention!