Views: 156 Author: Site Editor Publish Time: 2018-03-15 Origin: Site

Die casting process is a widely used metal technology in many industries, but in order to ensure the quality and efficiency of the die casting parts, you need to have a comprehensive and reliable inspection scheme for your die casting process.

Mainly in the following aspects:

1. Inspection of diecast sizes

2. Inspection of casting appearance

3. Chemical composition analysis

4. Inspection of die casting weight

5. Inspection of surface roughness

Specific inspection content:

1. Inspection of casting sizes

The die casting size shall conform to the requirements of the drawing. The casting machining allowance, as the key size of inspection, must conform to the requirements of the drawings, satisfy the cutting process.

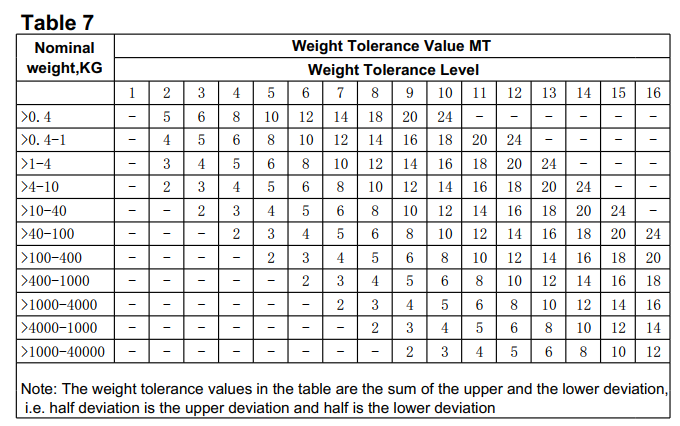

For the special sizes, the inspector shall be familiar with the drawing before inspection,and understand the key technical requirements of finished product. The size of the die casting deformation shall not exceed the machining allowance or the casting itself tolerance (as shown in table 1).

2. Inspection and control of casting appearance

2-1. Casting surface roughness.

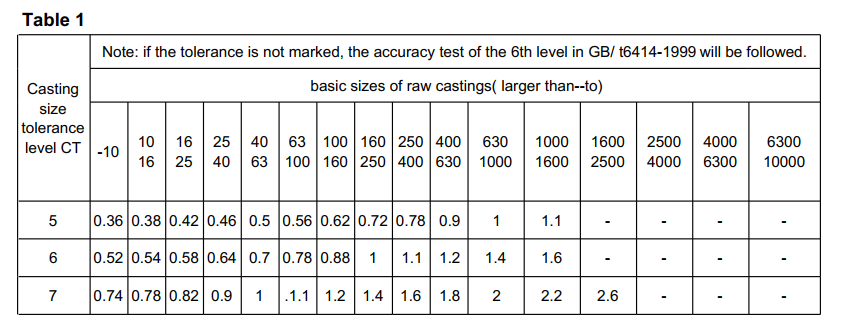

The diecast surface also can be compared by vision and sense of touch. The roughness of the non-machined surface is carried out according to the drawing requirements. The surface roughness of the diecast products can be tested according to GB/ t6060.1-199 (as shown in table 2)

2-2 Casting Defects.

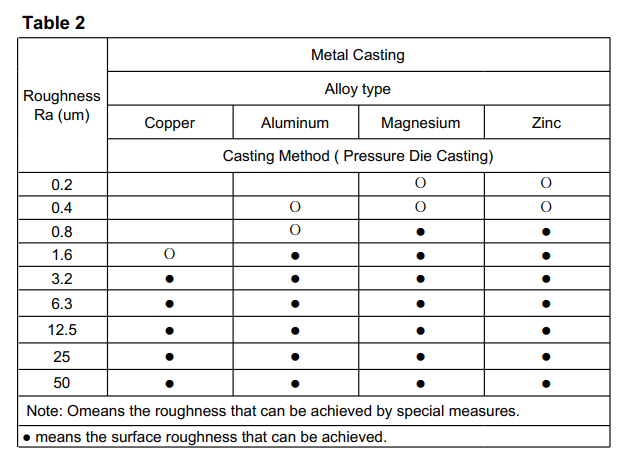

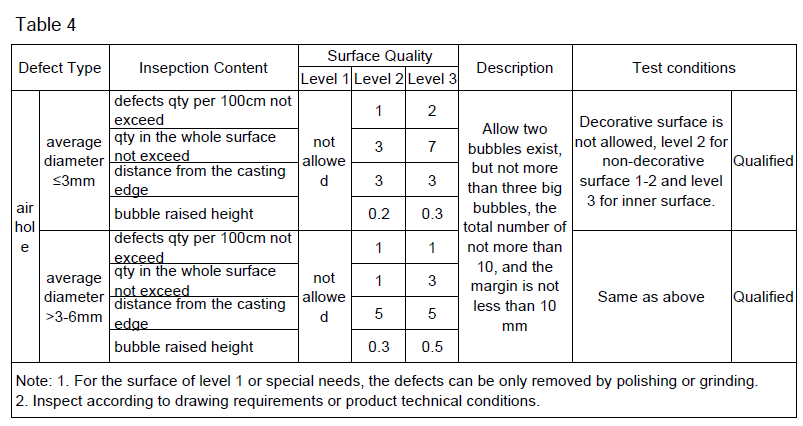

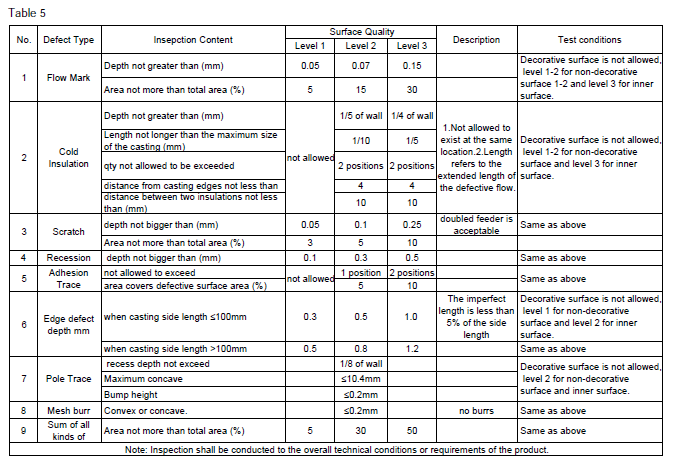

It is not allowed to have defect such as voids, pores, flying fins, under casting, looseness, warping, cracks and penetration. No adhesion foreign objects, burrs and bubbles are allowed on the surface and no sign of static ejector rod is not cleaned. It is allowed to have gate, flanging, sparing and separating, and cleaning traces on the top Plunger. The patterns, words, lines and symbols of the die casting must be clear. For the permitted gate, the surface of the casting part should be cleaned when the surface is not machined. According to the usage of diecast products, the non-decorative surface and internal surface defects of castings surfaces shall be acceptable as per the tables:

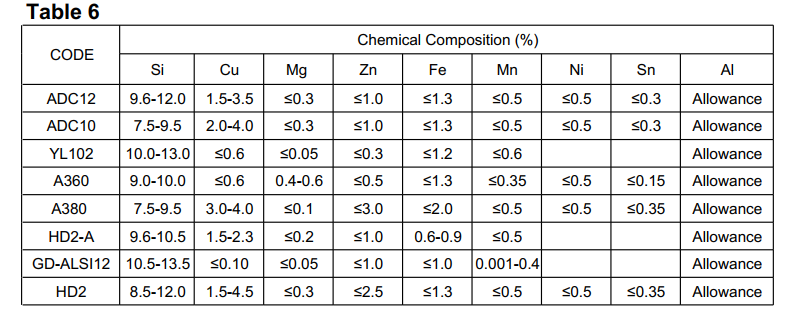

3. Chemical composition analysis

Based on the die casting material there are aluminum alloy die casting, zinc alloy die casting, magnesium alloy die casting and copper alloy die casting.The analysis of material composition structure is mainly from suppliers, and it is required to sign by authoritative institutions. Pls refer to the Standard Reference Table (mainly for zinc alloy and aluminum alloy used by our company) as below.

4. Inspection of casting weight

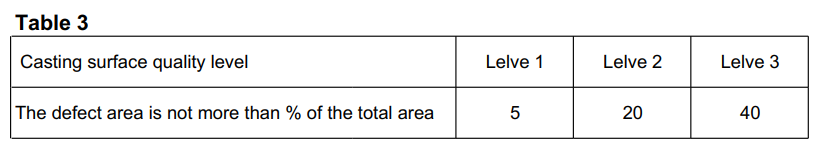

The weight of the die casting is also an indicator of whether the castings are qualified or not, and the weight tolerance also corresponds to the dimensional tolerance. For example, the size tolerance is CT6, and the weight tolerance is MT6. The weight tolerance level is shown in table 7.