Views: 26 Author: Site Editor Publish Time: 2020-10-09 Origin: Site

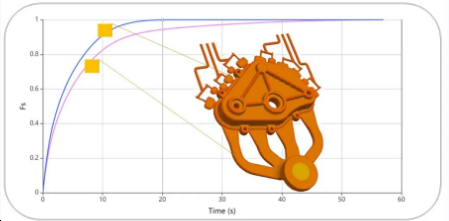

Mold retention time: the time from the end of the hold-down stage to the release of the die casting. The purpose of this time is to ensure that the casting is fully solidified, cooled and has a certain strength in the die, so that the die casting will not be deformed or cracked during the release and release.

Die castings with high alloy shrinkage, high thermal strength, thin wall, complex structure and fast die heat dissipation have short die retention time.On the contrary, the mold retention time should be longer

If the mold retention time is too long, it will cause difficulties in core-pulling and ejecting due to cooling, which may lead to tension and cracking and reduce the production efficiency.Too short die retention time can easily cause casting deformation, crown projection and surface bubbling.